Committed to serving industry and the planet

"We leverage holistic measures to achieve carbon neutrality"

“As global number one in steel abrasives, our ambition is to be a business and environmental leader. We offer environmentally friendly surface treatment solutions, and we are constantly working to reduce our environmental impact.

We are leading the industry in taking a green pledge to be carbon neutral by 2050, with a clear roadmap to reduce carbon emissions by 100 kgCO2eq/ton every decade. We are in pole position to achieve that: our emissions stand at a benchmark industry level of 300 kgCO2eq/ton or 6 times less than steel.”

Ramesh Krishnan,

CEO & Chairman

Green Pledge Ambitions

In addition, 95% of our raw materials are source d from recycling, 80% of our global waste products are repurposed, and our abrasives can be reused thousands of times before being re-cast as new. We have embarked on an ambitious program to reduce the energy intensity of our production. Whether major investments, such as innovative heat treatment, or smaller more modest ones, such as the installation of LEDs in the workshops, we use all levers, every degree, every kilowatt towards our goal. We are also investigating carbon capture technologies like molecular depositions. Above all, we take an end-to-end approach to the environment.

We partner with our clients on cutting-edge products and services that reduce their impact. Suppliers that commit to actions such as “Eco mobility” become Preferred Partners. And we are building the digital expertise that is an integral part of environmental leadership. Winoa is a world leader. We have the responsibility, the expertise and the passion to make our Green Pledge for our planet a reality.

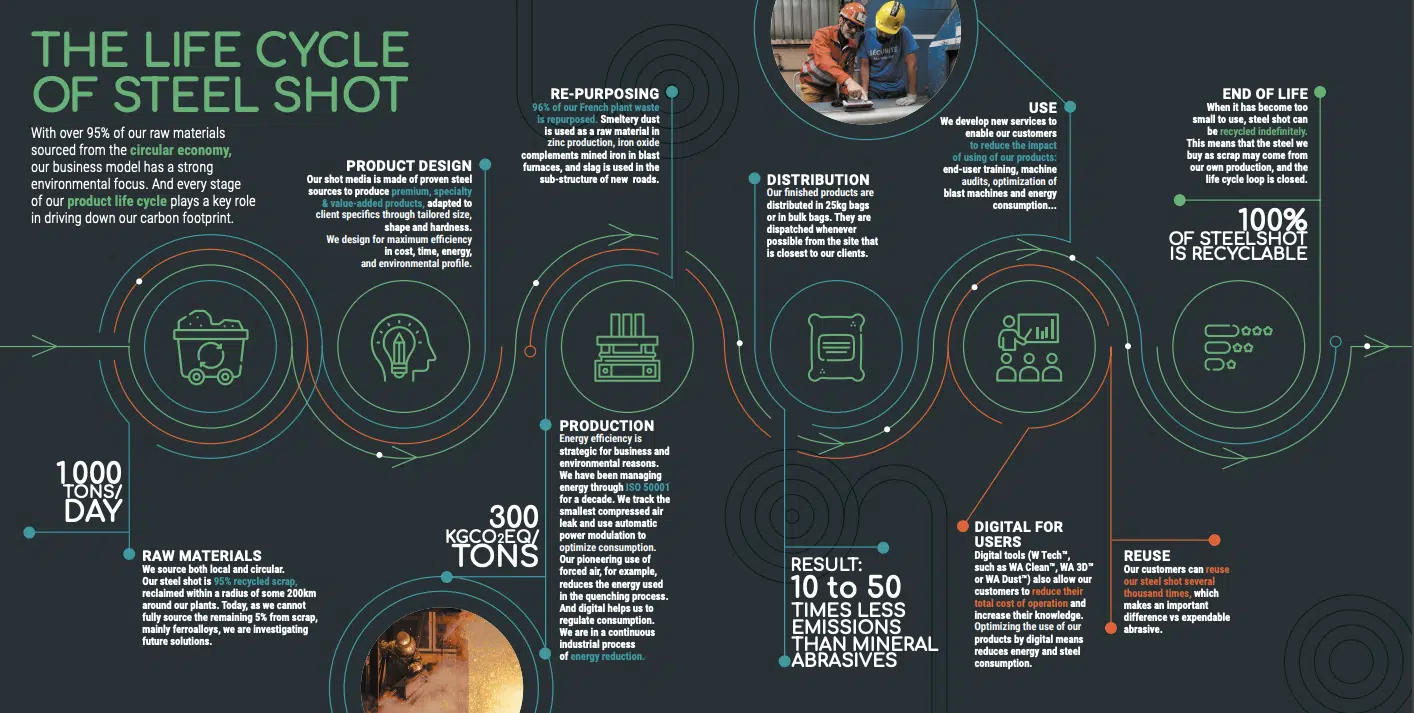

The life cycle of steel shot

With over 95% of our raw materials sourced from the circular economy, our business model has a strong environmental focus.

And every stage of our product life cycle plays a key role in driving down our carbon footprint.