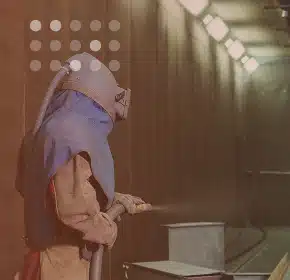

Shot blasting

Abrasive media

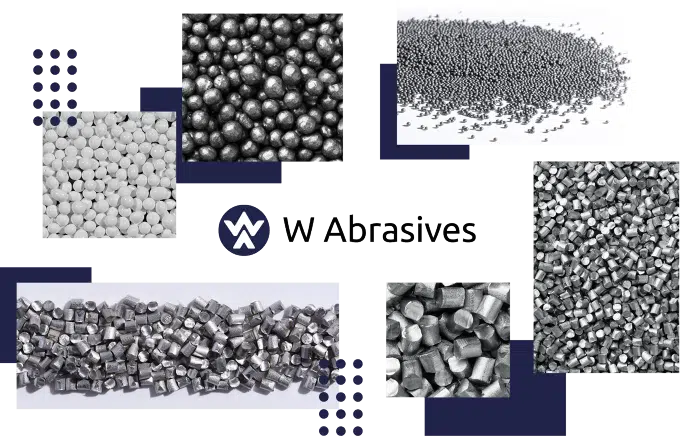

A complete range of metallic and non-metallic abrasives

W Abrasives

Every blasting media you need, everywhere in the world!

Among the metallic abrasives for shot blasting produced in our 8 plants, we find: high carbon cast steel shot & grit, low carbon steel shot, cast iron media, stainless steel abrasives, and cut wire shot.

WINOA also offers a range of non-metallic abrasive media, dedicated to specific surface treatment.

Our mission: to enable our customers to reduce their costs, while maximizing their operational performance.

Discover our range of renowned abrasives products

Shot blasting abrasives media

The efficiency of your shot blasting process relies on the quality of our blasting media & the know-how of our commercial and support teams.

Using our high performance or our Premium abrasives means choosing to produce faster, spending less energy.

To leave nothing to chance in your surface treatment, rely on our 60 years of expertise:

Key figures

5 applications

The great expertise of our teams in steel shot blasting media covers all the strategic applications you need

Why trust Winoa for your abrasive media shot blasting needs ?

As a pioneer and world leader in surface treatment, we are constantly investing to stay ahead of the market.

Our goal is to ensure that our customers benefit from the latest advancements in blasting abrasives !

Results: improved performance and efficiency!

Proximity

WINOA operates 8 production sites around the world, for cutting-edge logistics

Savings

Producing close to your plants drastically reduces transport costs

Excellence

In both stable quality products and reliable deliveries anywhere in the world

Innovation

Permanent R&D to provide products that perfectly meet the new expectations of our customers

Trust

Confrmed experts mastering the whole range of markets, for «preparing tomorrow’s surfaces»

Our responsible and sustainable commitments

We’re committed to environmental innovation and have set an ambitious goal of achieving carbon neutrality by 2050. We use only recycled steel scrap for our shot production and all our in-house produced products are designed to be completely recyclable and reusable, helping to reduce our environmental impact and contribute to a more sustainable future.

Achieving carbon neutrality

To achieve carbon neutrality, we are moving forward on a number of directions in the areas of water use, waste re-use, and people behaviour, including:

- all our production sites worldwide are ISO 14001 certified

- we are running a ISO 50001 program

- we already capture 99% of emitted dust particules

- heat recovery systems

- energy efficiency of HTS

- gas to electricity conversion

- reduced NOX emissions

- e-car policy and paperless offices

- closed loop water circuits

- self-generated electricity

- CO2 capture technologies